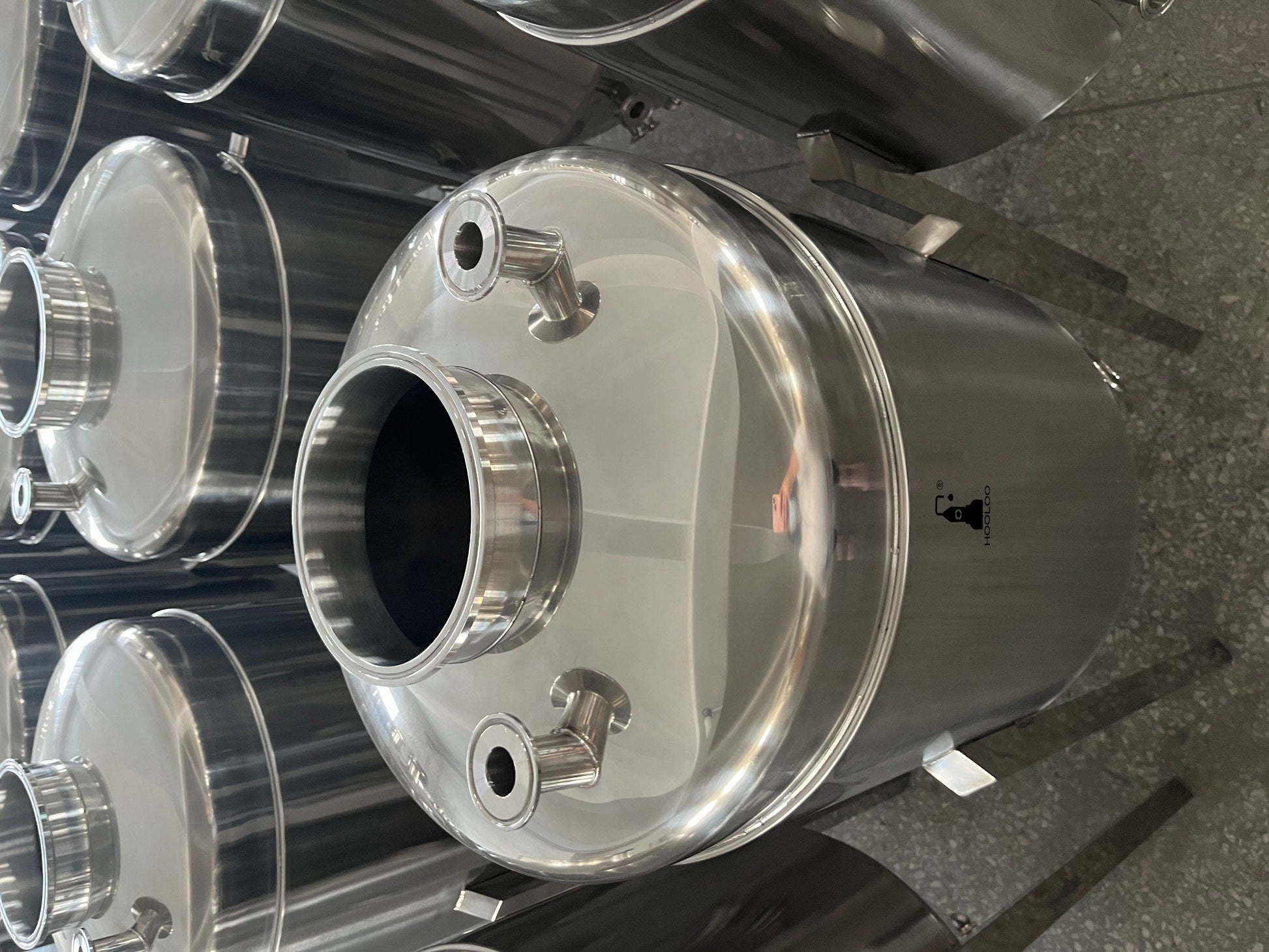

Double Layered Pressure Maintaining Fermentation Tank Craft Beer Equipment 304L Stainless steel For Beer/Whiskey(FOB Price)

Regular price

$1,039.00 USD

Sale price

$1,039.00 USD

Regular price

Product description

Shipping & Return

Stainless steel three-layer insulation and pressure resistant conical fermentation tank

-

Preferred food grade 304 stainless steel material, sturdy and durable, with a wall thickness of 3mm -

Incorporating a honeycomb sandwich structure into the tank walls serves a dual purpose: facilitating ice water circulation and enabling precise control over fermentation temperatures.

-

Expanding the fluid volume within the interlayer, shaped conically, significantly enhances temperature control capabilities, thereby optimizing the fermentation process.

-

A generous 5cm polyurethane foam insulation layer offers exceptional thermal insulation, ensuring that temperature fluctuations are minimized, thereby preserving the integrity of your fermentation.

-

Carefully selecting high-quality stainless steel accessories further enhances the overall durability and longevity of the setup, ensuring smooth operation over the long term.

-

The internal and external mirror surfaces, coupled with meticulously crafted cold-drawn pipe openings, not only contribute to a visually stunning appearance but also underscore the attention to detail and quality craftsmanship invested in the design.

1. Stainless steel adjustable pressure water seal valve x1

2. Stainless steel seismic pressure gauge x1

3. Quick connector x1 for intake and exhaust cola

4. Pressure relief valve x1

5. Sampling valve x1

6. Temperature blind tube x1

7. Wine taking rocker arm x1

8. Stainless steel duckbill butterfly valve x2 (3) 16. (Cleaning pipeline)

9. Sewage discharge mirror x1

10. Stainless steel sewage elbow x1

11. Several stainless steel clamps and washers 11. Bottom stainless steel reinforcement plate x1

12. Universal wheel x3 (4)

13. Stainless steel skin pipe joint

14. Reserve large diameter dry feeding port

15. Reserved observation port

16. CIP cleaning ball